A Refined Reflection Pool

This swimming pool appears to levitate just inches above the ground….

The key to this design is a look of effortless simplicity. The construction and finish work on this reflective vessel were no easy task. Perimeter overflow designs need a high level of expertise to ensure the engineering includes all the hidden components that truly make the pool function correctly.

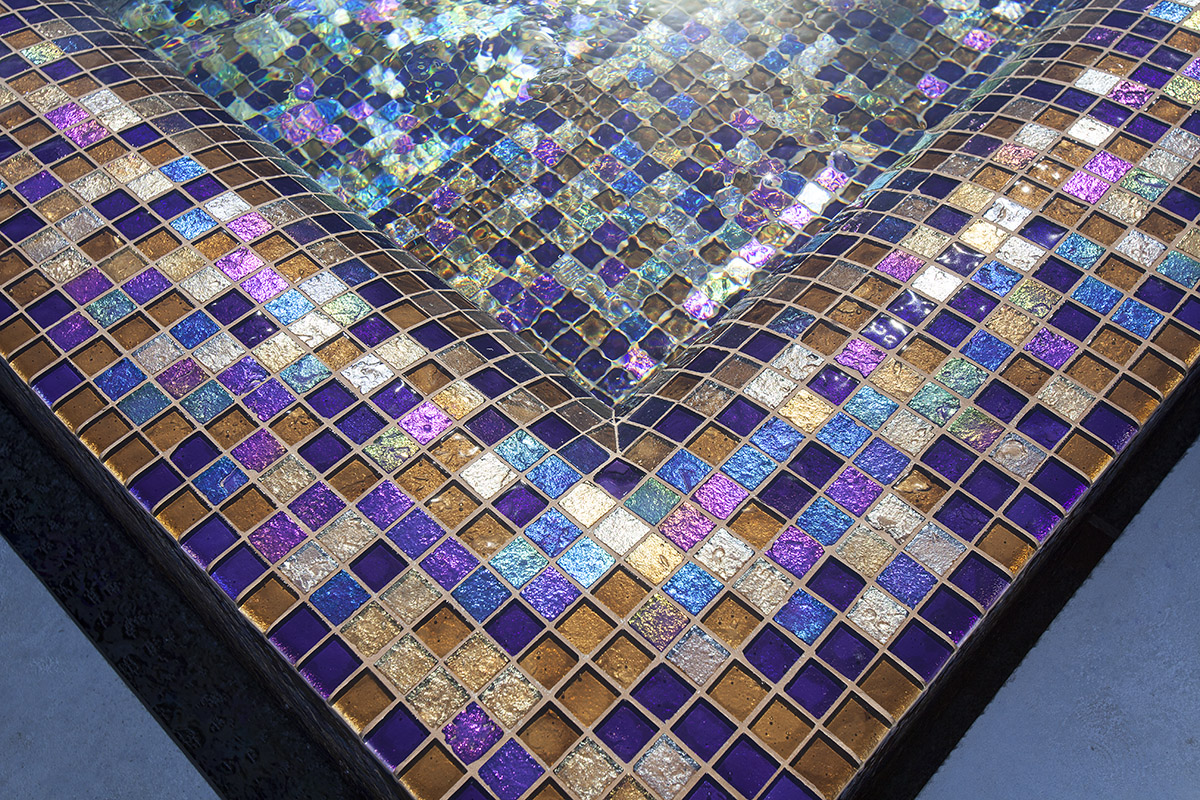

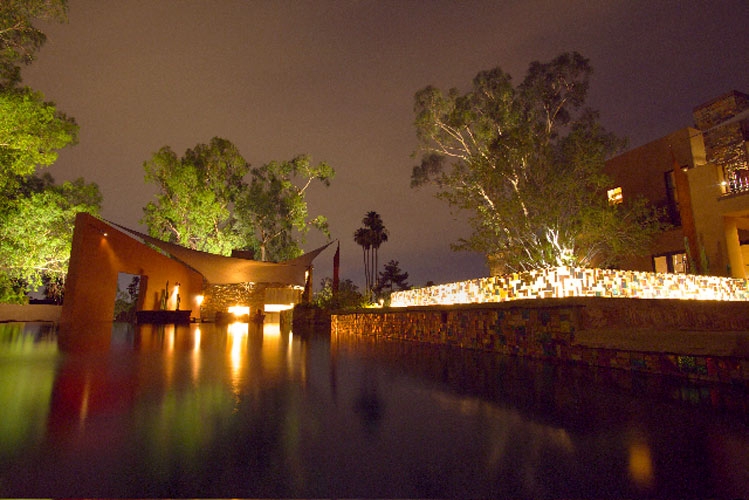

When designing a mirrored pool, the surrounding landscape, architecture and most import (!) lighting should be carefully considered. The massive reflective surface creates an opportunity for dynamic displays of specimen plantings, exterior artwork, and architectural details. Include a thoughtful lighting plan that softly washes areas you want to see in your pool’s mirrored surface.

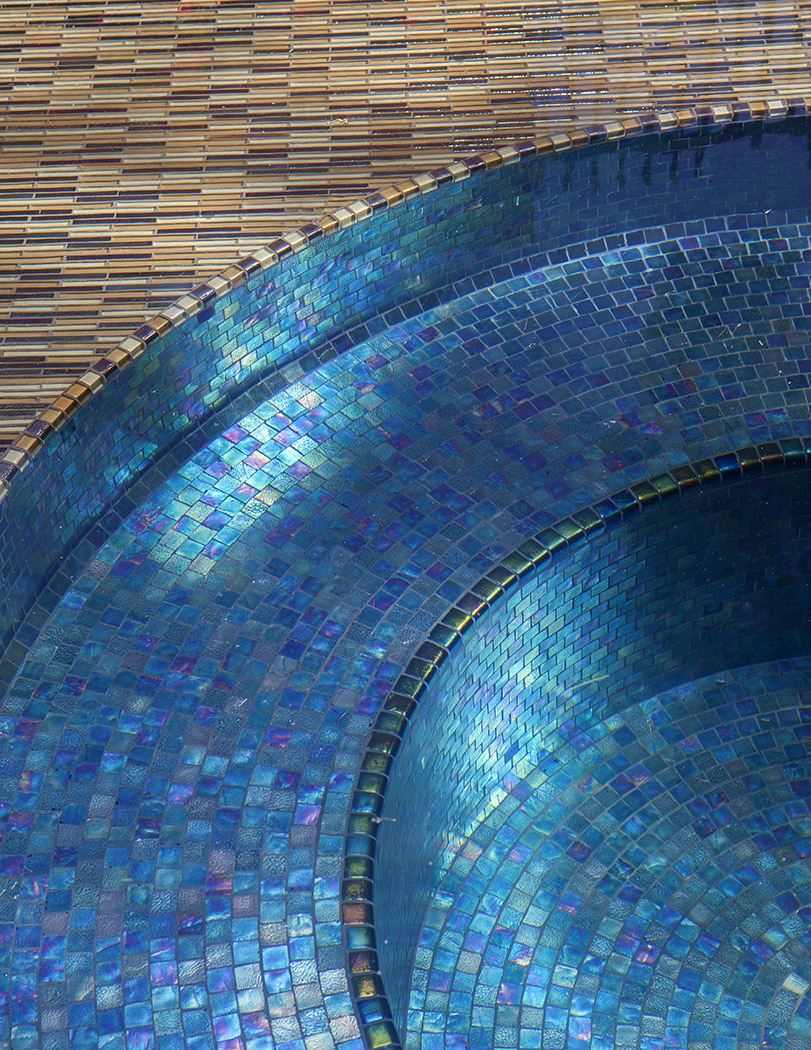

Our tile design calls for metallic glass mosaics on the top and exterior walls of the vessel, as well as the three steps entering the pool. We chose pewter glass mosaics from Oceanside Glasstile because in certain lighting, the tile disappears into the background. But from other angles, a reflective flash will shine through the mirrored surface of the pool. Black interior pebble finish will create the crystal clear mirror reflection.

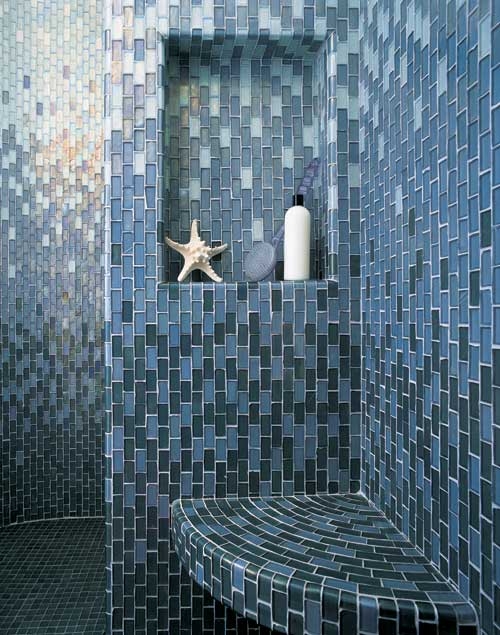

It’s important to know that glass mosaics should not be installed directly on a raw shotcrete shell. Surface defects, dimensional irregularities, and the non-water tight properties inherent to shotcrete are problematic for glass. The systems for proper installations vary and we have tested them all, pairing the best methods with the highest quality components to create what we believe is a perfect marriage of modern technology and time-honored installation arts.

Our proprietary process begins with cleaning, waterproofing, and then we spend considerable time planning. Here, Luke is preparing the knife-edge with mortar. During this time, he establishes the finished elevation of the pool, determines the pitch of the knife, and accounts for full tile layout.

After his float work is fully cured, he adds appropriate anti-fracture provisions and a white skim coat of thinset for protection. We are halfway through our projected timeline, and the substrate is now ready to receive tile.

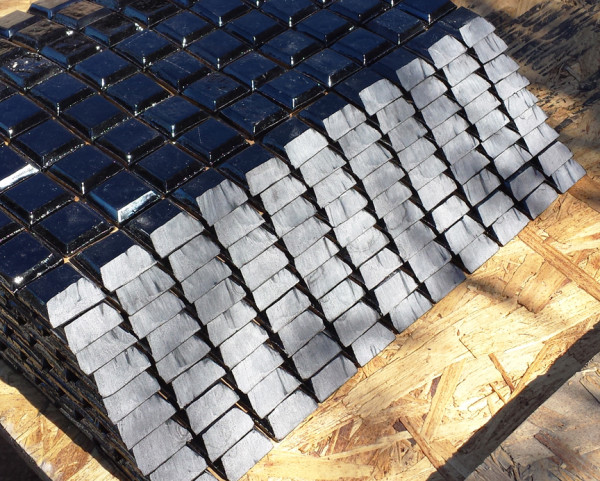

The aesthetic of this pool calls for precision planning in our installation. To create the cleanest outside corner on the perimeter overflow, 2,860 mosaic tiles are hand-mitered at 40 degrees, then remounted on paper sheets for installation.

Cutting on a wet saw minimizes heat stress when processing the glass.

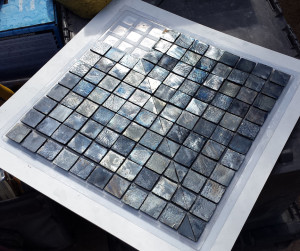

Mosaics mitered and re-sheeted, ready to go.

Luke begins installing, carefully checking that the entire perimeter is level.

Amy pre-cuts tiles that will wrap the corners before mounting them on paper.

The final touch on this design is hand-installing 1,750 mosaic quarter rounds on this inside corner. Because of their smooth contour, these little trim pieces guarantee no scuffs or scratches when swimmers slide in and out of the pool.

www.alpentile.com

Tile Design/Installation: Luke and Amy Denny, Alpentile 602-541-3065

Photo Credit: www.michaelwoodall.com

For more information about this pool and the products shown contact us here: